|

|

|

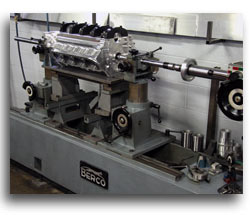

CYLINDER HEAD PORTING SERVICES:

The only way to spot a cutting edge cylinder head port developer is to investigate the equipment they have at their disposal. It does not take a grinder, an air compressor, and a garage; it takes expensive, sophisticated, technological equipment along with experienced people to get the job done right!

MMCE is a full service race engine machine shop that utilizes our CAD/CAM software, CNC machining capabilities, Serdi seat & guide machine, Saenz 680 Digital Flow Bench & accessories, among others to supply our customers with the latest and absolute best cylinder heads that the market has to offer!

Several cylinder head porting options are available:

Bowl Port & Gasket Match: This is our minimum recommended porting process. Takes care of the two most critical areas of the cylinder head. (Intake gasket match only.)

Super Modified Porting: Chambers, bowls, intake & exhaust gasket matching. If you're on a budget but looking for the best bang for the buck this is for you!

Full Port & Polish: Full hand porting & polishing of the chambers, complete intake port, & complete exhaust port. (Includes flow sheet.)

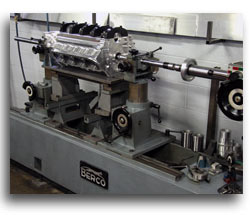

Full CNC Port & Hand Polish: Our in house CNC has allowed MMCE to provide the absolute best cylinder heads your hard earned money can buy. Our programs include ports for everything from various Big & Small Block Chevy, Ford, & Chrysler (Specializing in SB2.2, SBC Wedge, 23 degree SBC, conventional & spread port BBC to name a few). We cater to not only the drag racing market but have several ports for circle track applications as well. If we don't have exactly what you need (which is unlikely) we can modify current programs or create an entirely new program to fit your needs! Every process from programming, digitizing, CAD/CAM development and solid modeling are all done in-house under one roof. This alone enables us to tweak any variable to fit your needs.

Cylinder head port development is never complete. Once a company "settles" it is quickly passed by. That is why we at MMCE constantly spend countless hours tweaking, changing, & re-designing existing ports to ultimately end up with best the industry has to offer!

MACHINING OPTIONS TO CONSIDER DURING PORTING: Race Recondition: Includes Clean & Inspect all Components; Race Valve Job; Grind Valves; Inspect Guide Clearance; Flat Mill; Install 16 Valves to Specified Chamber; Check & Correct Proper Valve Spring Installed Height; Inspect Proper Open & Closed Pressures, Coil Bind, and Free Heights; Install Springs; Vacuum Test Individual Chambers; Assemble Heads. Competition Valve Job: Cut Multi-Angle Competition Valve Jobson Serdi 100. (per pair) A necessity for ported cylinder heads to achieve optimum air flow.

Valve Profiling: Produces dramatic increases in low lift flow for additional horsepower and torque. A good option for ported heads. Includes machining proper back angles on the valves. |

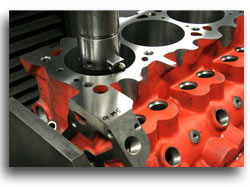

BLOCK MACHINING SERVICES:

We've found early on that to do things correctly you must have full control over them! That is why we spare no expense when it comes to equipment to machine cylinder blocks. We are able to perform any machining task when it comes to a cylinder block. From a simple bore & hone to complicated raised dry cam tunnel conversions....we can do it all!

Several block machining operations are available:

Bore & Torque Plate Hone: This is a typical procedure that the majorities of automotive machine shops perform but has to be approached correctly or it can lead to many disastrous problems for your engine program. We have the ability to not only indicate o of the existing bore but the dowels as well. With state of the art machinery at our disposal you can be assured that you are receiving the most accurate cylinder bore available.

Machine Deck of Block: MMCE utilizes not only our CNC machining capabilities but also our wide selection of BHJ equipment to make sure that your block has the correct deck height dimensions as well as the correct angle.

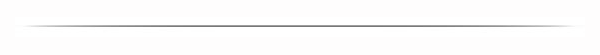

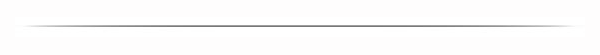

Align Bore & Hone Main Line of Block: Owning one of the few Berco line boring machines in the country allows our customers to take advantage of machining abilities that are hard to find. Several machines try and duplicate what the Berco has perfected. This is the only machine of its kind that can be versatile enough to handle any type of block, but be accurate enough to hold tight tolerances even with the largest of housing bores. We can not only align hone mains but we can bore repaired blocks in house!

Align Bore & Hone Cam Tunnel of Block: The Berco also allows us to repair cam tunnels as well. With mandrels and bars from big to small we can repair or enlarge the cam tunnel in your block to exacting specifications.

Lifter Bushings: Again with a full line of CNC equipment and BHJ tooling at our disposal lifter bushing installation and machining becomes a very easy process. We perform everything from standard lifter bushing repairs to exotic custom location keyway lifter installs. Valve train is critical....you want to make sure lifter placement is ideal and correct for your application or it will result in power loss or even worse broken parts.

Needle Bearing Cam Conversions: Along with lifter bushing installation, needle bearing camshaft conversions are our specialty! As power increases the responsibility of the camshaft increases. The larger the barrel on the camshaft the more rigid it becomes inherently reducing the flex and deflection in the valve train equating into more power. We perform BBC Babbitt, 50mm, 55mm, 60mm, 65mm, 70mm, and even 75mm conversions on some of today's most popular block choices.

Miscellaneous Operations: We are a fully equipped facility that has the ability to perform just about any machining operation possible to a cylinder block. From stroke clearancing, O-ring & receiver groove machining, and sleeve installation to welding & repairing blocks and more, we do it all!

|

|

|

ROTATING ASSEMBLY SERVICES:

As many components and assemblies that are included in a high end competition engine build from other manufactures, the rotating assembly gets lost in the shuffle. Many engine builders believe that as long as you have a 4340 steel crankshaft, a forged piston, and an H-beam rod you have yourself a "racing engine". This could not be further from the truth. There is an untold amount of HP potential trapped within the components of the rotating assembly that we @ MMCE have managed to unlock! As much attention to detail goes into every rotating assembly that we build or sell as any component we offer.

Several rotating assembly services available are:

Crankshaft Grinding: MMCE covers a wide range within this category. From standard undersized grinds to custom 1 off "Honda" pin conversions and 283 mains to the Nitride and hardening processes....we have you covered!

Crankshaft Lightening: For a select few crankshafts we do offer a very intense lightening process. If you are looking for a great diet to put your rotating assembly on, contact us!

Spin Balancing of Rotating Assembly: Spin balancing is a service that M&M Competition Engines has been offering longer than almost anybody in the business today! We have all of the state of the art equipment to balance your rotating assembly properly. Pain staking efforts are made to balance all assemblies to the nearest 1/2 gram where other companies in the industry consider 20 grams to be "close enough".

We also offer "No Holes" balancing to cut down on windage!

Custom Piston & Rod Machining: When it comes to rods & pistons we offer some of the most exotic and purpose specific options available on the market today. If you are looking for a full round skirt, "slipper" skirt, custom ring pack, custom hollow dome, exotic lightweight rod bolts, short lightweight titanium pins, custom application built rods, etc.... please contact us. We have years of experience within this realm and our knowledge could save you thousands of dollars and hours of agonizing labor, all it takes is a phone call! |

TOOLING & FOUNDRY SERVICES:

WE BEGIN FROM YOUR CONCEPTS & IDEAS:

This is a typical procedure that the majorities of automotive machine shops perform but has to be approached correctly or it can lead to many disastrous problems for your engine program. We have the ability to not only indicate o of the existing bore but the dowels as well. With state of the art machinery at our disposal you can be assured that you are receiving the most accurate cylinder bore available.

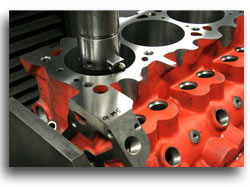

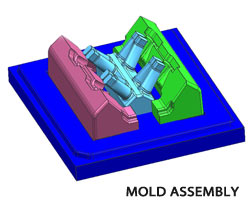

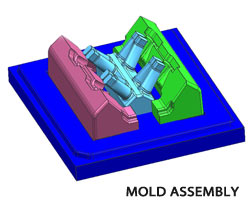

IN HOUSE MOLD DESIGN:

From the design process above we proceed onto the next step. We utilize the CAD drawing information and produce computer generated mold assemblies to enable us to CNC machine all of the tooling in house. CNC tooling insures that all of the casting features are exact and precise and can be reproduced or altered at any time with very little effort. Producing our tooling in this fashion also allows us to verify all of the data integrity that goes into the casting. A wide range of dimensions and specifications are verified before we even start cutting the first part.

TOOLING NEVER LEAVES OUR HANDS:

Once we have completed the mold assembly drawings and verified their integrity we supply you the customer with a complete verification package for you to view and sign off on the project (again before we even begin cutting the tooling). Once everything is confirmed we take the CAD produced mold assembly and begin cutting the tooling in house on our CNC milling center to produce the best tooling in the industry!

YOUR FINAL PRODUCT MACHINED & READY TO MARKET:

Our tooling programs insure that you get the product that you are looking for. Every contract includes a minimum 5 piece order of the product to insure not only you but ourselves that your part is the best it can possibly be. With this 5 piece sample run it allows us to confirm that the tooling is properly constructed for the foundry process and that machining the product will not reveal any surprises. Keeping everything in house allows the process from idea - design - machining - and final product to be a seamless and efficient one.

|

|

|

CUSTOM SERVICES:

What sets us apart from others in this industry is the fact that we encompass a wider range of services than any other! We not only provide our customers with the best standard machining services but we also offer several services that others cannot reproduce. We truly are a "1 stop shop"!

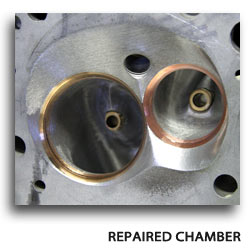

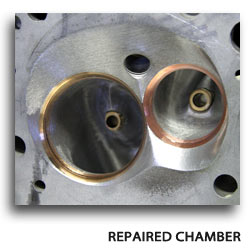

Cast Iron & Aluminum Welding: Cast iron and aluminum cylinder head and block repair has been an ongoing part of MMCE for several years. If you have a project that needs repaired give us a call. One of the few companies that actually repairs cast iron and aluminum correctly. Cast iron repairs are performed in an oven heated to custom heat settings to enable the repaired area to be stronger than the original material. We can repair cast in either brass (brazing) or one of the few shops in the country that can also repair in actual cast iron.

Cast iron and aluminum cylinder head and block repair has been an ongoing part of MMCE for several years. If you have a project that needs repaired give us a call. One of the few companies that actually repairs cast iron and aluminum correctly. Cast iron repairs are performed in an oven heated to custom heat settings to enable the repaired area to be stronger than the original material. We can repair cast in either brass (brazing) or one of the few shops in the country that can also repair in actual cast iron.

Cryogenic Metal Treating: We also offer cryogenic metal treating process that extends the duty cycle of just about any material and part. This is quoted by the job so please give us a call to discuss your needs.

Chemical Cleaning for Iron & Steel: Want your old iron block or cylinder heads to look like they did the day the mold was broken at the foundry? Now you can with the chemical cleaning process that we have. It is only available for iron and steel components but it will give them an as new appearance inside and out to begin your next project with clean parts that are worthy of the build! |

|

|